[email protected]

+61 415 035 742

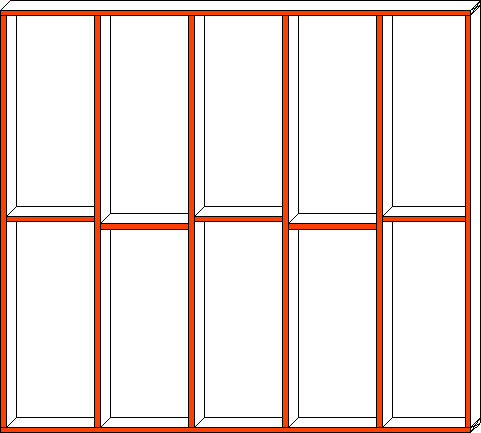

Prefabricated timber wall frames built to predefined specifications.

This is the most economical option for prefabricated wall frames.

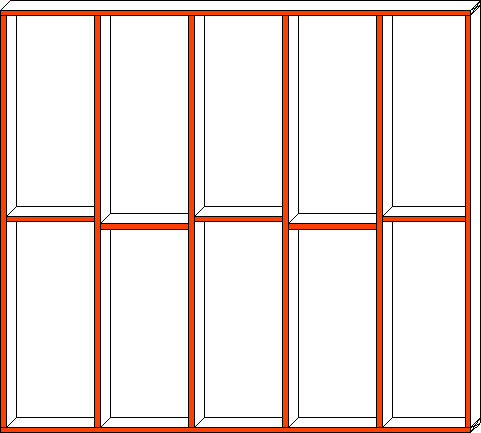

Prefabricated timber wall frames built to your specifications.

Use this tool for bespoke frames to suit specific requirements.

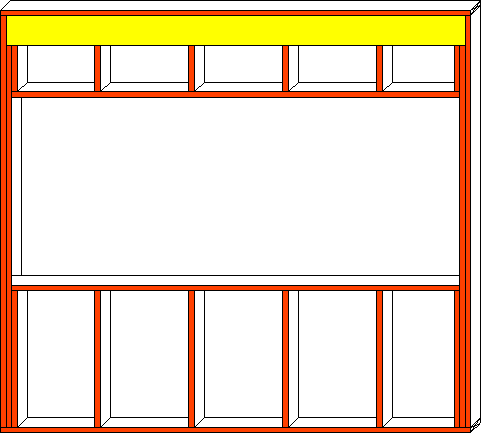

Standard framing components to suit common window and door opening sizes.

To be used in conjunction with other wall frame components.

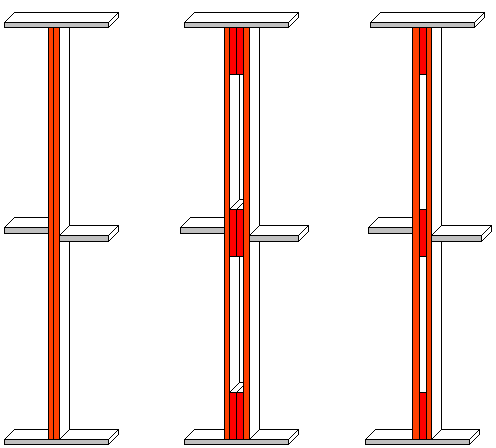

Ancillary framing components like corners, junctions, double studs, and loose timbers.

To be used in conjunction with other wall frame components.